Even for existing equipment without drawings, we can support customization, development, and improvement.

At NFT Co., Ltd., we offer comprehensive support for the modification, improvement, and customization of existing equipment.Leveraging the expertise we’ve gained through years of experience in mold and encapsulation equipment manufacturing, we provide tailored solutions to help improve yield and boost productivity at your site.No drawings? Dealing with outdated equipment? Looking to enhance automation or safety? Don’t worry—we’ve got you covered.From semi-automating manual machines to full automation, reducing labor time, and improving operational efficiency, we deliver practical improvements directly connected to your production floor.

Precision Molds

Small-Lot Production & Prototyping

We support small-lot production and prototype molds, responding to detailed customer requirements.

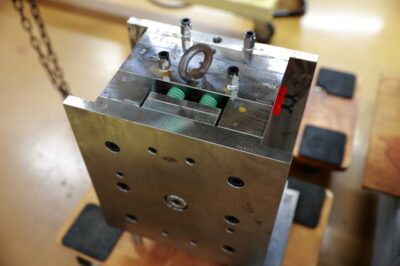

Resin Encapsulation Molds for Semiconductors

We manufacture and prototype a wide range of molds for discrete devices, ICs, power devices, lenses, and more, always ensuring molds meet product specifications.

Injection Molds

We manufacture molds for connectors, relays, cases, and bases. We can handle even palm-sized parts—please consult us for details.

Resin Encapsulation Equipment for Semiconductors

Customization & Development

We listen to customer needs and customize equipment accordingly, providing rapid after-sales support.

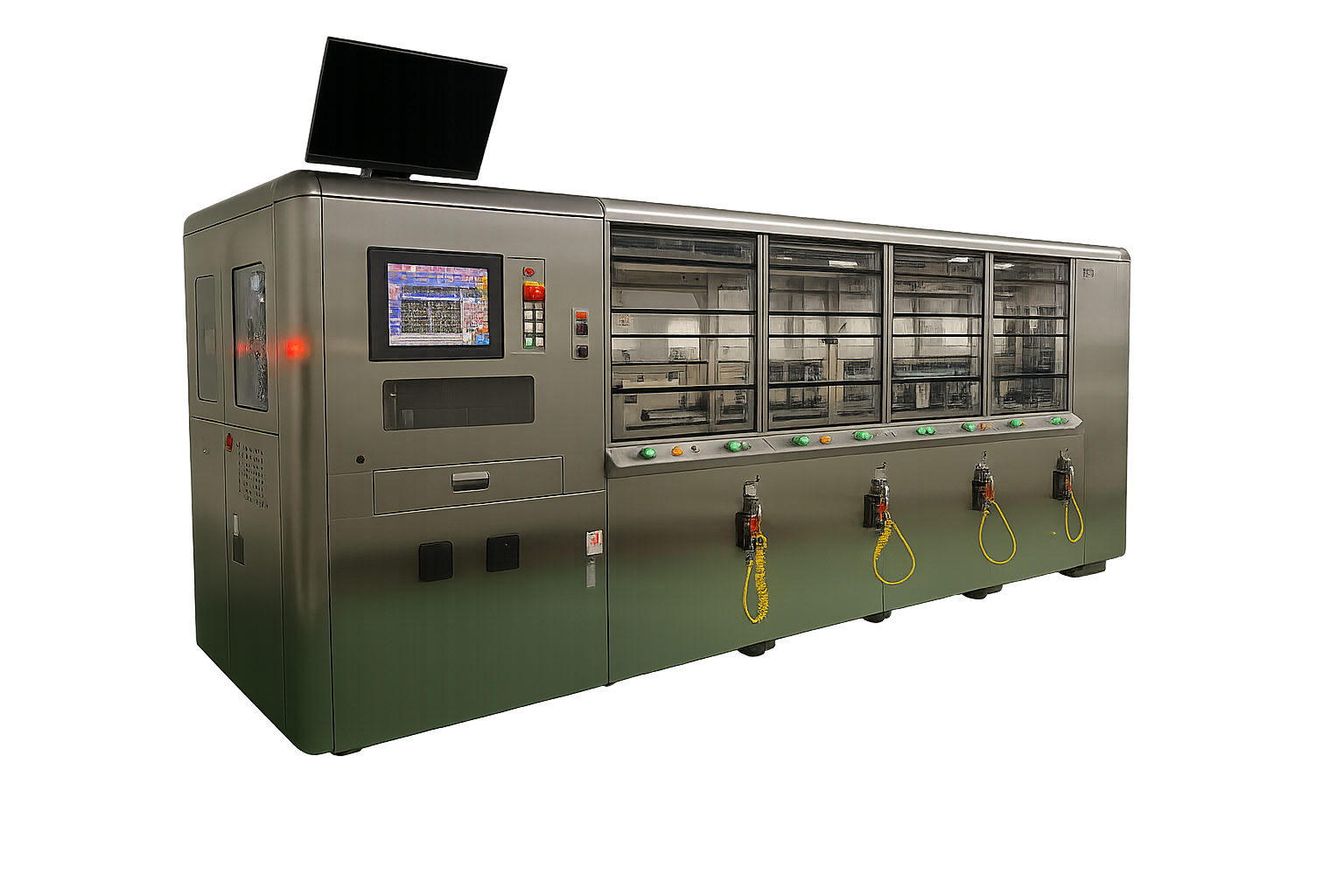

Across2byX Series

A high-volume model with multiple presses (up to 5). Using linear motors for transport, machine time is reduced to as fast as 15 seconds. Conversion to other product types is possible in as little as 30 minutes. Presses not in use during automatic operation can function as manual presses, eliminating downtime for mold cleaning.

AcrossR2

A multi-product model with a single press. Quick conversion between product types is possible in as little as 30 minutes. The center turntable simplifies drive components and enables an efficient layout.

Across2 / Across4 / Across8

Custom models tailored to customer needs, including press capacity, mold size, product size, and even cover color.

AcrossH

Designed for reel-type frames, supporting 1-row and 2-row operation. Can be manufactured to match existing gate-cut molds.

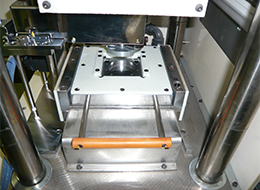

Manual Press

We can manufacture the system according to the specifications and layout required by the customer.It supports a wide range of mold sizes and press capacities—from prototype applications to various production needs.Hydraulic plungers, vacuum molding, and other optional features are also available.

Applications: Prototype molds

For overseas markets

Wide range of press capacities

Hydraulic & vacuum degassing molding

Options Include:

Hydraulic control, vacuum degassing, heat sink transport, automatic mold release, spraying, auto-cleaning, and many others. We apply our accumulated expertise in mold and encapsulation equipment manufacturing to propose the most suitable solutions.

Peripheral Equipment / Existing Equipment Modifications

Automation Equipment

Frame Loader

Capable of handling 2-piece molds up to conveyor-compatible frames. Available in fully automatic or semi-automatic configurations.

Automated Inspection Equipment

Equipment to inspect chip misalignment, bent leads, and package printing.

Pelletizing Machine

Automatically converts powdered semiconductor encapsulation resin into pellets, customizable to required pellet shapes.

Spiral Flow Tester

Enables in-house spiral flow testing and root-cause analysis for defects.

Resin Characteristic Tester

Allows in-house measurement of gel-time standards for quick assessments when needed.

TF Equipment

Customizable to customer requirements, including laser markers and integrated image inspection systems.

Even Without Drawings, Existing Equipment Is Not a Problem.

Support for Customization, Development, and Improvements

Existing Equipment Modifications

Even without drawings, we can assist with customizing or upgrading your existing equipment. We leverage accumulated experience in yield improvement, productivity enhancement, semi-automation, full automation, labor reduction, and safety improvement. We can handle modifications to existing devices, whether manual, semi-automatic, or fully automated.

Spare Parts & Hard-to-Find Components

If you need parts that are difficult to source, or components without drawings, model numbers, or manufacturer information, we can assist in locating or fabricating them.