Grinding Machining

Problem

“Our prototype required extremely tight dimensional accuracy, and other suppliers often failed to stay within tolerance.”

Solution

“High-precision grinding with surface roughness Ra 0.05 or less and machining accuracy of ±1 μm.”

Previously, additional adjustments and re-polishing were required during the finishing process. With our grinding technology, target dimensions can now be achieved directly during machining.

This eliminates misalignment during assembly and ensures stable product accuracy. As a result, mold life has been extended, and post-delivery defects have been completely eliminated.

Customers have praised our work, saying they can “entrust their projects to us with confidence.”

Grinding Machining

Problem

“Material changes caused grinding burn and dimensional shifts, increasing finishing time.”

Solution

“By selecting the optimal grinding wheel and conditions based on material characteristics, we achieve stable, burn-free machining.”

By understanding the grinding behavior of each material, burn and warpage have been nearly eliminated.

Parts that previously required long finishing time can now achieve stable quality in the first pass.

This has resulted in shorter overall lead times and reduced costs across the entire process.

Customers have expressed high satisfaction with the improved finish quality and consistent results.

High-Speed Machining

Problem

“Tool breakage and inconsistent surface roughness occurred when finishing micro features.”

Solution

“A 45,000-rpm high-speed spindle combined with ultra-small tools enables stable mirror finishing and micro machining.”

The combination of a high-speed spindle and ultra-small tools allows mirror finishes to be achieved consistently.

This reduces or eliminates the polishing processes once required, shortening overall machining time.

Surface quality has improved significantly, giving products a more premium appearance.

Customers have praised the results, saying the finish is “beautiful and faithfully reflects the original design intent.”

High-Speed Machining

Problem

“We couldn’t determine the optimal machining conditions for each material, resulting in variations in dimensional accuracy and surface finish.”

Solution

“By setting cutting conditions based on material characteristics and applying our machining expertise, we achieve high precision and stable quality.”

Optimized machining conditions tailored to each material’s hardness and thermal properties have nearly eliminated dimensional variation—even across different material types.

This allows consistent quality from prototyping to mass production.

As a result, rework and inspection-related backtracking have been greatly reduced, providing significant benefits in both lead time and cost.

The consistently high-quality finish also supports our customers’ next stages of product development.

Die-Sinking EDM

Problem

“Electrode fabrication and EDM machining were outsourced separately, making setup and scheduling complicated.”

Solution

“By handling electrode design, fabrication, and EDM machining in-house, we eliminate process-to-process inefficiencies.”

Completing everything from electrode design to machining within our facility has significantly reduced coordination time between processes.

Design changes can be handled on the same day, greatly accelerating development speed.

Quality variation has also been minimized, and rework has become almost nonexistent.

Customers appreciate the reliability of both our delivery timelines and product quality, saying they can “entrust the entire process with confidence.”

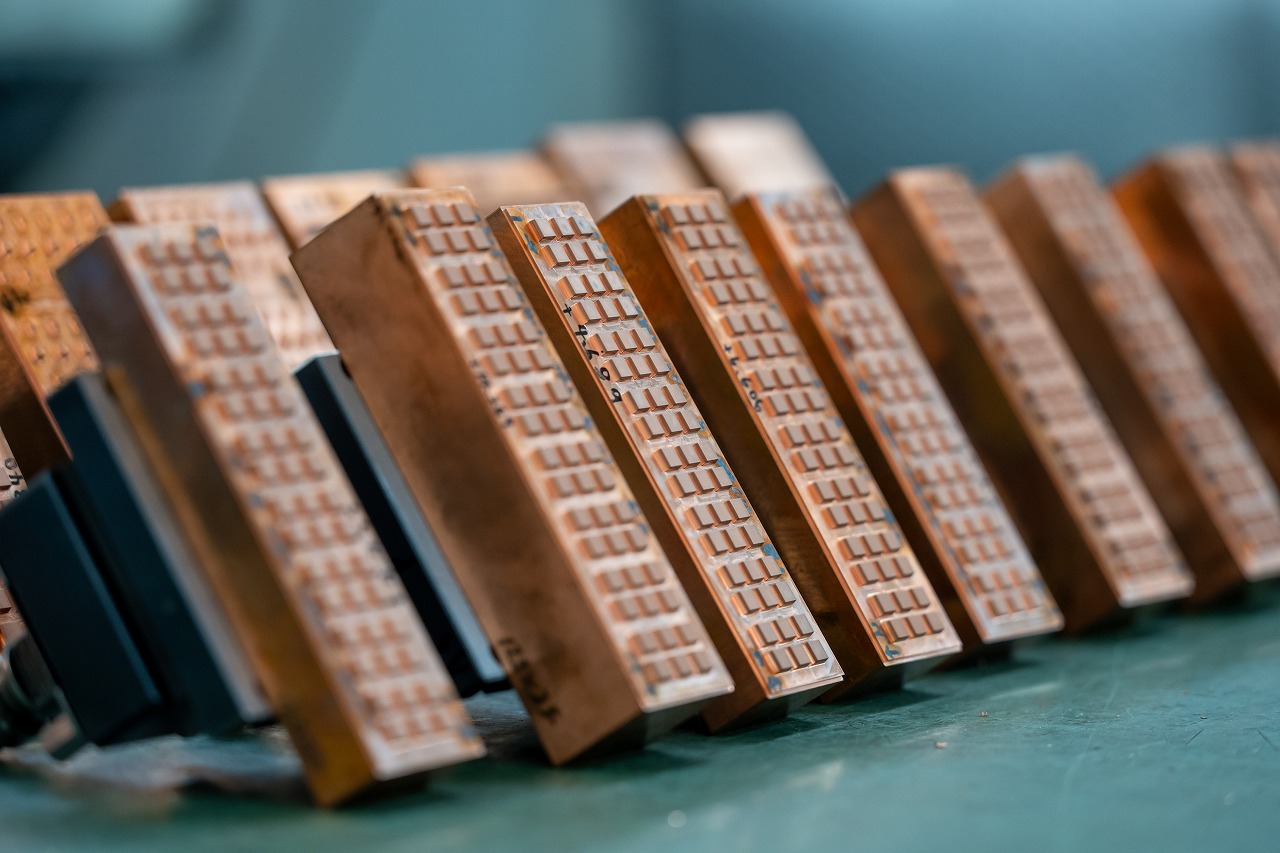

Die-Sinking EDM

Problem

“Micro-feature and deep-rib EDM machining resulted in shape deformation and dimensional variation.”

Solution

“By selecting copper or graphite electrodes based on the machining requirements, stable processing under optimal conditions is achieved.”

By leveraging the distinct characteristics of copper and graphite electrodes, micro ribs and deep grooves—previously difficult to reproduce—can now be machined accurately.

This ensures uniform finishing even in detailed areas, reducing polishing work on the mold.

As a result, stable supply is possible even for components requiring high precision, and design flexibility has significantly increased.

Wire EDM

Problem

“Cutting extremely small geometries was difficult, and the intended design shape could not be accurately reproduced.”

Solution

“Using ultra-fine φ0.07 mm wire, even narrow sections and micro-features can be machined with high precision.”

Ultra-fine wire machining allows stable reproduction of micro-scale shapes that previously exceeded conventional machining limits.

This capability enables greater flexibility in product designs aimed at weight reduction and higher component density.

Customers have expressed surprise, saying that shapes they once considered “impossible” can now be achieved.

As a result, this technology is widely used in prototypes for new product development.

Wire EDM

Problem

“Dimensional deviations occurred during long machining operations due to temperature changes and wire elongation.”

Solution

“Advanced equipment with automatic temperature compensation and wire-elongation control ensures stable machining accuracy.”

Even during long nighttime or unmanned operations, dimensional shifts caused by temperature fluctuations or wire elongation have been eliminated.

Consistently stable accuracy reduces the need for post-machining inspection and correction, resulting in improved overall process efficiency and lower costs.

This highly reliable “high-precision automated machining” has earned strong repeat orders from many customers.

Small-Hole EDM

Problem

“When machining small holes in hardened steel or carbide materials, tool wear and chipping occurred frequently.”

Solution

“By selecting copper electrodes ranging from φ0.1 to φ5, we established stable machining conditions even for difficult-to-cut materials.”

Small-hole machining—once challenging on carbide and hardened steel—can now be performed with high stability, greatly reducing design constraints.

Tool chipping and wear have also been minimized, enabling consistent dimensional accuracy even during long machining operations.

As a result, reliability in mass production has increased, allowing us to respond more flexibly to our customers’ production schedules.