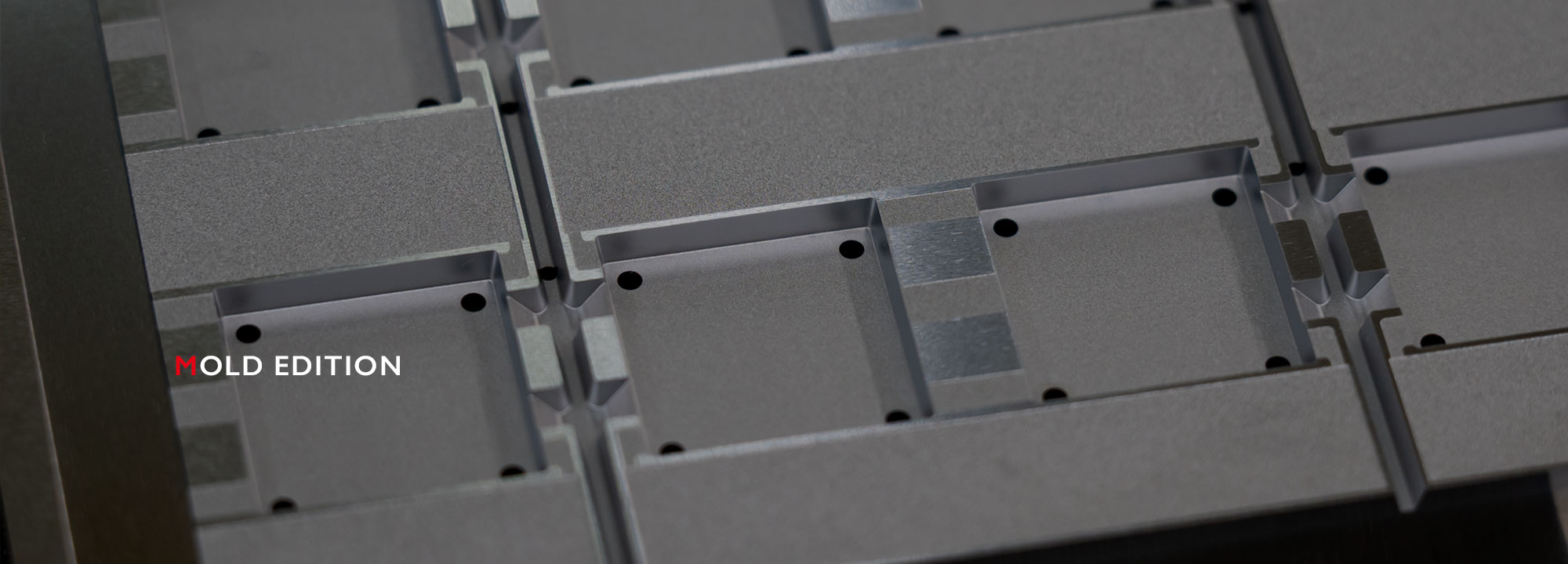

Power PKG: Flash Burr Countermeasure for Heatsink Sections

Problem

“During molding, resin flows into the heatsink section, causing numerous thin flash burrs, making post-processing labor-intensive.”

Solution

“Control resin flow with finely machined special recesses on the cavity surface, precisely reproduced using both EDM and machining methods.”

Flash burrs are now almost entirely eliminated, greatly reducing the removal process.

Surface quality has stabilized, and mold maintenance frequency has decreased.

As a result, yield has improved significantly, achieving both production efficiency and quality.

Customers have highly praised the solution, noting that “stability during mass production has improved dramatically.”

On-Site Mold Trial in Thailand

Problem

“We want to conduct mold trials in Thailand without shipping molds overseas.”

For overhaul molds, no mold manufacturers in Thailand can perform trial shots, so all molds must be sent back to the country of manufacture, resulting in significant time and cost.

Solution

“Test-press trials available at NFT Thailand for on-site support.”

At our Thailand facility (NI Thailand), trial press operations can be conducted locally, allowing attendance by local engineers and contributing to their skill development.

Additionally, because molds do not need to be shipped overseas, transportation costs and lead times are significantly reduced.

Molded Product Prototype: Fast Delivery and Quality Assurance

Problem

“We need reflector product samples urgently.”

To secure orders from end-users, prototype molds must be produced as quickly as possible and samples delivered, while still ensuring high quality.

Solution

“Rapid delivery and proprietary surface finishing.”

Immediately after receiving the order, we conducted same-day design meetings and expedited design and fabrication to deliver the prototype mold, meeting the requested sample deadline.

Additionally, our proprietary surface finishing ensured uniform product surfaces, satisfying quality requirements.

Lens Package: Void Improvement

Problem

“Voids cannot be eliminated.”

Voids in the transparent resin of lens packages are persistent! Changing molding conditions alone was insufficient to remove them.

Solution

“Resolved with a degassing unit.”

By introducing the manual press AcrossM with a degassing unit, combined with digital control of degassing, pressing, and transfer timing, optimal conditions can be easily achieved, eliminating voids.

In addition, NFT mold design—considering cavity count, dummy cavities, corner radii, and draft angles—improves not only void elimination but also mold release performance.

Increased Maximum Cavity Count to Ensure Profit

Problem

“We want to secure profits for discrete (general-purpose) products.”

Increasing the maximum number of cavities is necessary to maintain profitability.

Solution

“Significantly increased cavity count through mold design changes, achieving 7,072 PKG/shot.”

Easy Adjustment of BGA Product Thickness

Problem

“We want to easily change the product thickness.”

Previously, changing the thickness of BGA products required replacing the entire set of cavities, making the process complex and costly.

Solution

“Thickness adjustment achieved by replacing spacers.”

By redesigning the upper mold with a nest-type cavity, and leveraging NFT’s precision in cavity surface EDM and spacer thickness polishing, we can meet strict product thickness requirements for our clients efficiently and cost-effectively.

Improved Lifespan of Movable Pins and Sleeves

Problem

“The lifespan of movable pins and sleeves is short (2 months).”

In power semiconductor packages, the short lifespan of movable pins and sleeves leads to lost production opportunities and higher lifecycle costs.

Solution

“Tripled lifespan of movable pins (6 months) through hardness enhancement.”

Using NFT’s proprietary technology, we increased the hardness of the movable pins by more than double, successfully extending their lifespan threefold.

Power Mold Wear Countermeasure

Problem

“Gate and runner sections of power molds wear out quickly, resulting in a short lifespan.”

Sealing resin for power semiconductors contains a high amount of silica. With standard mold surface treatment (HCr, hardness HV800–1000), the molds are too soft, leading to rapid wear.

Solution

“Tripled mold lifespan through surface treatment modification.”

By changing the surface treatment of the gate and runner sections and increasing hardness to over twice the original (HV1800–HV2000), we successfully extended mold lifespan threefold.

Reduction of Upper/Lower Mold Misalignment Adjustment Time

Problem

“Adjustment of upper/lower mold misalignment with existing molds reduces productivity.”

The mold misalignment tolerance was very strict, making fine adjustments difficult, and even reassembly often failed to resolve the issue.

Solution

“Significantly reduced adjustment time using eccentric guide blocks.”

We manufactured eccentric set blocks that can be adjusted directly on the press. By reusing key components, we resolved mold misalignment cost-effectively and successfully shortened adjustment time dramatically.

Lead Resin Bleeding Improvement

Problem

“Resin bleeding on the lead section causes plating defects.”

Even after changing the frame to address plating defects, the issue persisted. There was a need to investigate whether mold adjustments could solve the problem.

Solution

“Improvement through polishing the parting surface.”

Typically, the parting surface is polished along the longitudinal direction. To counter base resin bleeding caused by the L/F substrate rolling direction, we polished the parting surface along the short direction (perpendicular to the L/F rolling direction), successfully reducing resin bleeding.

Resin Leakage Countermeasure: Fine Groove Machining

Problem

“Resin leakage from slit-type packages cannot be stopped.”

Resin from WBGA slit-type packages was leaking onto the substrate ball pad area, causing poor yield and production issues.

Solution

“Create multiple fine grooves alongside the package to stop leakage.”

Using NFT’s design and polishing expertise, we successfully added two fine grooves within a 0.5 mm area, effectively preventing resin leakage.