We create what our customers truly need, using development expertise built across diverse industries since our founding.

NFT Co., Ltd. provides a wide range of services including the design, manufacturing, development, assembly, and maintenance of precision molds, semiconductor manufacturing equipment, related parts, and peripheral units.With over 20 years of proven technical expertise and a trusted track record of deliveries to 11 countries worldwide, we offer optimal solutions to meet our customers’ needs.For more details about our services, please refer to the following page.

Precision Mold Manufacturing

Development & Design

Since our founding, we have leveraged development technologies accumulated across diverse industries to produce exactly what our customers need.

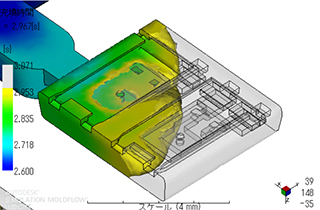

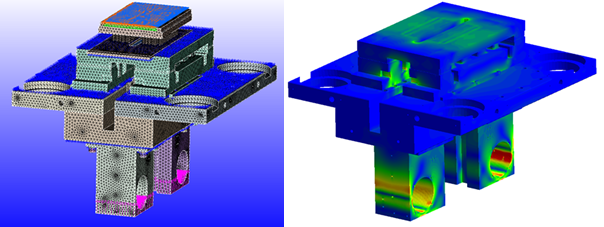

Mold Design

For semiconductor packaging molds, please contact us. Based on over 20 years of in-house design experience, we provide new mold designs, improvement proposals for existing molds, and prototype mold design. We also handle reverse engineering by receiving parts or molds. Our goal is to deliver the optimal semiconductor process for each customer.

Equipment Design

We design and manufacture transfer mold equipment. Our lineup accommodates high-volume production as well as small-lot, multi-product production. We can also handle any special specifications, producing exactly what customers require.

Development

Using the development tools and technologies accumulated since our founding, we provide the latest solutions tailored to customer requirements. We work closely with customers to identify problems and create effective solutions.

Precision Metal Processing

High-Precision Processing × Short Lead Time

Grinding

We can manufacture a wide range of semiconductor molds, and recently have produced sensor-related lens shapes in-house. We also produce parts according to customer specifications.

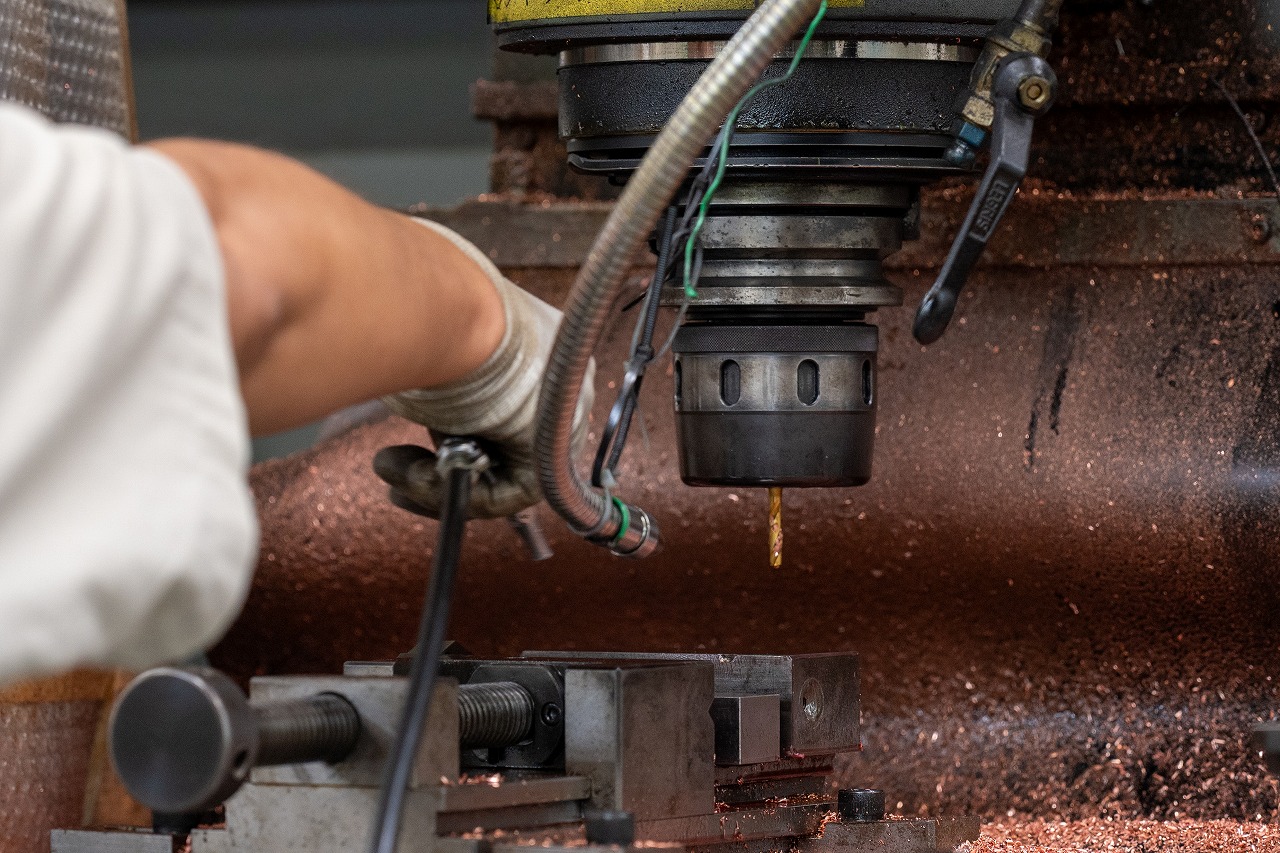

Milling

From resin to ultra-hard metals and ceramics, we provide processing for plate materials, high-precision micro machining, and 3D shapes using linear machining centers.

EDM (Electrical Discharge Machining)

With increasing precision and complexity of products, EDM plays a critical role. We operate 10 EDM machines, handling IC packages, lens shapes, and ultra-fine machining, enabling us to meet a wide range of customer needs.

Finishing / Polishing

We polish complex cavity shapes and optical lenses using skilled techniques. We also provide micro-blasting for improved mold release, deburring with glass beads before processing, and cleaning.

Surface Treatment

Proper surface preparation is essential. Using NFT’s proprietary techniques and functional plating selection, we deliver surface treatments that exceed customer expectations.

Assembly & Mold Trial

Mold Assembly / Trial Press

All molds manufactured in-house are assembled and trial-pressed internally. We provide total support from manufacturing to production start, ensuring immediate readiness. We also offer mold diagnostics and modifications to resolve issues as needed.

Equipment Assembly

We provide comprehensive support from proposals and assembly to adjustment, inspection, installation, and after-sales follow-up. Even overseas, we train engineers in operation, maintenance, and troubleshooting to ensure stable production from the start. For any issues, our engineers respond promptly with just one call.

Aerospace Sector

We provide precision part processing for aircraft, including prototypes and specialized jigs. We support everything from single units to small-lot production, offering high-quality, high-precision machining for diverse aerospace needs. We also focus on automating handling systems, contributing to production efficiency and quality stabilization. From development and design to mass production, we support customers throughout the process.

After-Sales Support & Maintenance

After-Sales Support

After in-house prototyping, we provide complete support through final product verification, including adjustments on actual equipment. If issues arise, our engineers visit the customer site to resolve problems directly.

Maintenance

Regular maintenance of molds and equipment ensures long-term optimal performance. We perform periodic overhauls that reach areas not covered by routine maintenance, allowing early repair and improvements, and supporting stable production processes.