3-Carrier Auto Mold System: Continuous Automatic Molding Including Heatsink Frames

Problem

“It was not possible to mold heatsinks and L/F stacked two layers, making automation difficult.”

Solution

“The Across2byX series was upgraded to a 3-carrier configuration, enabling continuous molding of different L/F types within a single machine.”

Previously, multiple L/F molding steps were done in separate processes. Now, one machine can handle them in a single cycle, eliminating setup changes and manual transfers. This greatly improved continuity and stability, making the system suitable for flexible, multi-product production lines.

In-Mold Image Inspection to Reduce Defects

Problem

“Post-molding visual inspections revealed many defective products, resulting in poor yield.”

Solution

“An image inspection system was integrated inside the molding machine, enabling automatic detection of defects immediately after molding.”

Defects can be identified and removed in real-time, greatly reducing defective products in subsequent processes. This also reduces inspection personnel while stabilizing quality. The accumulated anomaly data can be used for root cause analysis, enhancing traceability.

Built-In Cooler for Resin Management

Problem

“Temperature increases caused resin degradation, leading to molding defects.”

Solution

“A cooler was installed inside the machine to maintain a consistent resin temperature until supply, preventing degradation.”

Stable resin temperature improved product accuracy, stabilized molding conditions, and prevented defects such as bubbles or filling unevenness. Seasonal or operational temperature fluctuations are minimized, enabling consistent mass production and easier material management while enhancing quality assurance reliability.

Simplified Resin Supply Structure

Problem

“Complex structures with many parts made regular maintenance time-consuming.”

Solution

“The hoop system was redesigned, simplifying the resin transfer system for easier replacement and adjustment.”

Maintenance time was significantly reduced, machine downtime decreased, and operational efficiency improved. Part replacement and cleaning became easier, lowering maintenance costs. Despite the simpler structure, high rigidity and stable operation were maintained, reducing operator workload.

Automatic Preheat Up/Down: Controlled Heating Only for Required Time

Problem

“Excessive preheating could negatively affect the product, so minimal preheat was desired.”

Solution

“The preheat unit was automated to move up and down, allowing heating only for the required time.”

Optimizing the heating timing immediately before molding minimized thermal expansion effects on the product, keeping them within design specifications.

Integrated Vacuum Unit for Efficient Machine Cleaning

Problem

“Cleaning dust and resin debris inside the machine required vacuum preparation, consuming a lot of time.”

Solution

“A vacuum unit was integrated into the machine, enabling immediate cleaning.”

Cleaning time was reduced, machine uptime increased, and sensor false detections or mold contamination from dust were prevented. Operator cleaning workload was reduced, ensuring a safe and clean work environment. Routine maintenance became easier, improving long-term operational stability.

All-Stainless Steel Covers for Hygiene and Durability

Problem

“Paint peeling or rust on the machine surface caused aesthetic deterioration and increased the risk of foreign matter contamination.”

Solution

“The machine covers were replaced with all-stainless steel, improving cleanability and corrosion resistance.”

Appearance and cleanliness are maintained long-term, and the risk of foreign matter contamination is reduced. The system is now compatible with cleanroom environments, and adoption has expanded in facilities with strict hygiene and quality standards. Maintenance burden is reduced, resulting in a long-lasting, highly reliable machine.

Real-Time Monitoring of Molding Quality with In-Mold Pressure Sensors

Problem

“We could not identify the causes of internal filling defects or voids in molded products, leading to quality variations.”

Solution

“Pressure sensors were installed inside the mold, enabling real-time monitoring of injection pressure during molding.”

This makes it easier to optimize molding conditions and suppress internal defects. Pressure data can also be used for quality control and preventive maintenance.

By visualizing molding conditions, stable production is achieved without relying on the intuition of experienced operators, improving efficiency in training and skill transfer.

2byX Series: High Throughput with 4-Tablet 2-Column Structure

Problem

“We want to increase production volume, but the number of products per machine cycle was limited.”

Solution

“The 2byX series was customized to a 4-tablet 2-column structure, doubling the number of products molded simultaneously.”

This significantly increased the number of products per cycle and improved production capacity. Mass production was achieved without adding more machines, reducing capital investment while attaining high throughput. Cycle time was also shortened, establishing a highly cost-effective production system.

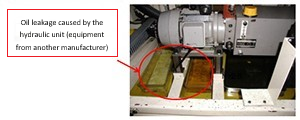

Troubleshooting Existing Equipment

Problem

“Issues with aging equipment.”

Some equipment problems cannot be resolved because the original manufacturer is unable to provide support, or the manufacturer no longer exists.

Solution

“Handled by N.F.T.”

With extensive experience in manufacturing and repairing parts for other companies’ equipment, we can assist in resolving equipment issues.

When problems occur, we can inspect the equipment on-site and conduct discussions to determine the appropriate measures.

Automation of Mold Release Shots

Problem

“Frequent mold release recovery shots are required, reducing productivity.”

Every time, the machine had to be stopped to perform mold release recovery shots manually. Production efficiency needed to be improved.

Solution

“Added automatic mold release recovery shot function to N.F.T Auto Mold press.”

During production, automatic mold release recovery shots can be performed at any desired frequency, significantly increasing productivity.

Example of Productivity Improvement

(Assuming 1 mold release shot is required per 20 shots per hour)

Before Improvement (Manual Mold Release Shot)

6 min per shot + operator + 4 min for start/stop = 10 min

20 shots / 70 min = 17 shots/hour

After Improvement (Auto Mold Release Shot)

3 min per shot + (no operator) + (no start/stop delay) = 3 min

20 shots / 63 min = 19 shots/hour

⇩⇩⇩⇩⇩⇩

Productivity increased by 12% and labor costs reduced!

Productivity Improvement Through Automation of Mold Release Agent Spraying

Problem

“We want to automate manual molding and mold release agent spraying.”

For products in production, mold release agent must be applied. To prevent uneven spraying, it had to be done manually, requiring one operator per press, resulting in low efficiency. To simultaneously improve production efficiency and reduce labor costs, automation of the molding equipment is essential.

Solution

“Developed equipment with an automatic mold release agent spraying mechanism.”

By equipping the press with spray nozzles, mold release agent can be applied as part of the entire molding cycle. The nozzle tips are designed to prevent dripping and clogging, greatly improving maintainability.

Compared to existing manual presses, productivity is increased by 10% annually.

*Eligible for tax incentives under the productivity-improvement equipment promotion system.

Productivity Improvement Through Mold Process Automation

Productivity Comparison

Existing Equipment: AcrossM-60 (Manual Press)

| Cure Time:sec | Injection Time:sec | Manual Time:sec | Total Cycle Time:sec*1 | Production per Press(pieces/hour) |

| 180 | 24 | 60 | 264 | 27.2 |

*1 Measured by the customer with all tasks performed manually: substrate/frame setup, mold release agent spray, and removal of molded products.

Latest Equipment: Across2by2-120 and Across2by3-60 (Auto Mold Press)

| Cure Time:sec | Injection Time:sec | Manual Time:sec | Total Cycle Time:sec | Production per Press(pieces/hour) |

| 180 | 24 | 15 | 219 | 32.8 |

21% Productivity Improvement

Notes

For products requiring mold release agents, the existing equipment only supported manual spraying using the AcrossM manual press. By adding an automatic spraying mechanism, multiple auto-mold presses can now be used, reducing the total cycle time by 45 seconds.

Regarding the Across2byX series:

・Across2by2 uses 2 presses, achieving 66 pieces per hour (141% increase)

・Across2by3 uses 3 presses, achieving 99 pieces per hour (263% increase)